The kit for this build of an LMS 6-wheel insulated milk van was made in the early 1970s by W&T Manufacturing [Birmingham] Ltd. One of two pre-Nationalisation 6-wheel vehicles that they made, it comprises white-metal castings, plastic card, wood, some brass and an acetate body shell, it also has screen-printed plastic-film sides to attach. Assembling this kit is very much a return to old-fashioned modelling: screws and nails and a pin-hammer, alongside super-glue. Attaching the sides will require impact-adhesive however, to ensure as flat a fit as possible. Given its age, whether it will be possible to produce an acceptable end-product remains to be seen, but nothing ventured....

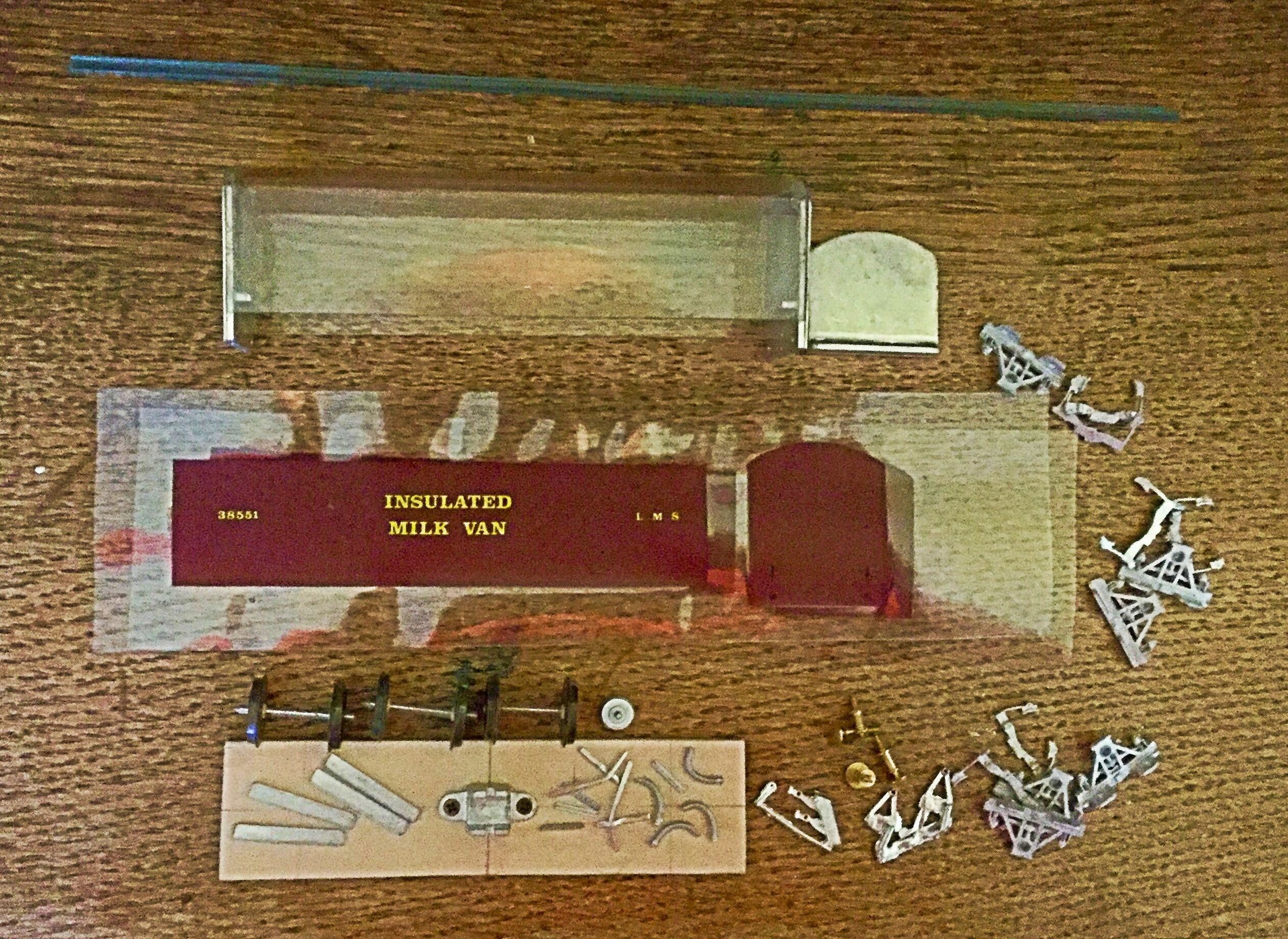

On opening the box and inspecting the contents, it quickly became apparent that the kit will present some challenges in construction. The white-metal castings were generally quite good but the acetate 'tunnel' which is the body shell will be tricky. It is overlength by around 3mm and is very flexible/flimsy [but not flexible enough to lie flat to scribe and cut]. Further, it will be difficult to attach it to the white-metal ends as instructed because there is little surface to glue it to [a shallow rebate on each cast end]. Consequently, it's already obvious that it cannot be easily made in the way that the instructions suggest. The constituent parts are shown below, with the body assembles as a dry-fit to check length. The floor has been marked up to accept the various white-metal castings.

Elsewhere in this Workbench is a description of the build of a W&T Palethorpes van. As this build more-or-less mirrors that build, I will limit the text to odd notes and provide photographs to show progress, rather than write an identical description here.

The photograph opposite shows the body shell assembled: the acetate ‘tunnel’ has been cut to length and attached to the white-metal ends with impact adhesive. The plywood floor was also trimmed to the dimensions given in the paper template and attached as a dry-fit at this stage. With the floor in place, the whole unit is quite stable.

The next photograph shows the underside of the chassis once the brake cylinder, sole bar, axle boxes and centre axle holder have been attached. Careful measurement was essential to keep the axle box / W-iron castings square and they have been attached with small nails in pre-drilled holes.

Above, a side view of the chassis. The cast axle-box / W-iron assemblies are commendably fine. The partition in the middle, a white-metal casting, will provide support to both the sides and the roof. It may need a little filing in due course. All that now awaits fitting to the chassis are the brake levers.

Finally, the finished product. The thin acetate sides and ends [see above] were cut from their sheets and attached with impact adhesive, the chassis having been completed and glued to the upper body shell. The printed sides and ends had shrunk slightly through age unfortunately and this is a little noticeable [although touched-up]. Rainstrips have been added to the roof also. However, cruel though the photograph is, in reality, the model looks a little better in natural light and on a track. The floating centre axle enables the van to travel through complicated track geometry and tight curves with ease and the whole ensemble provides a welcome alternative to the similar Hornby offering which, whilst the latest iteration has an excellent livery application, still runs on its decades-old, crude 6-wheel chassis.

But was this old kit really worth persevering with? I suppose I’d have to observe that the Palethorpes van [see elsewhere on here under ‘Bangers and Mash’] was a more satisfying and far better-detailed build. Still, it was possible to make something out of this particular kit of parts even though the overlays were a little short, particularly at the ends. The sides would have been a better fit had the floor been reduced in length certainly, and the chassis adjusted accordingly. But there was little that could realistically be done to improve the ends and the rounded profile of the tops of the cast metal end-pieces rather accentuates the problem. However, we are where we are and whilst running, none of this is really noticeable. It is, after all, vintage modelling and not quite a sow’s ear…..